Main Menu

E-mail:sales@scmcpcb.com

Website :www.scmcpcb.com

Skype:sc.mcpcb

No minimum order quantity

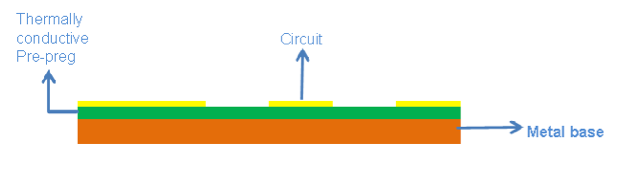

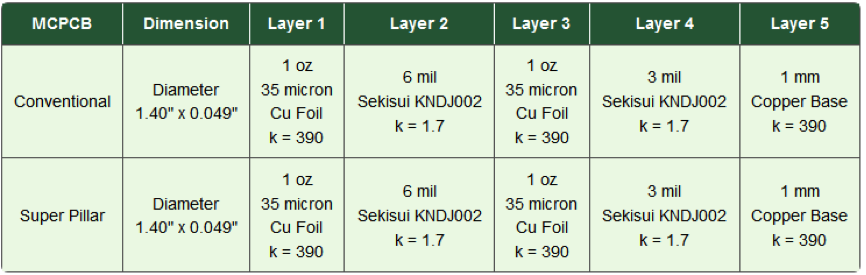

Super Pillar copper PCB is a upgrade of traditional copper PCB. A traditional copper PCB structure includes copper foil, dielectric, and copper plate. Copper foil serves two major functions, first, conducting current, and second, conducting heat. Dielectric, PP, is to provide heat conduction and insulation. Copper plate is used for dissipation and becomes a media for heat sink attachment to provide advance heat dissipating.

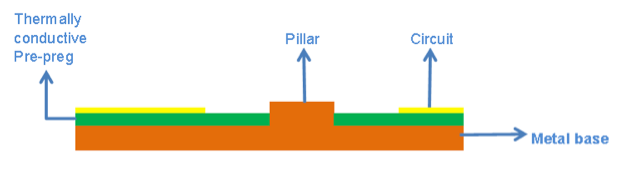

Looking dielectric found inside the traditional copper PCB, it covers entire copper plate completely which is designed for heat dissipation. On the other hand, dielectric inside the Super Pillar copper PCB doesn’t cover entire copper. It leaves some openings. In these specific areas, the copper are exposed on top of dielectric and solder mask. Creating a protruded copper pillar that penetrates dielectric and becomes an extension of copper plate.

Most of traditional copper PCB we found on the market. The coefficients of heat conductivity of dielectrics are between 3~4W/m-K. Of course, we can find 5W or even higher from the market. However, the copper plate beneath the dielectric has coefficient of heat conductivity around 400W/mK accordingly. It is clear that they have much better heat conducting performance than dielectric on top of them. This is causing dielectric to become the bottle neck of heat conducting & dissipating in traditional copper PCB.

The invention of Super Pillar copper PCB is the best solution to overcome that bottle neck found in traditional copper PCB. Combining Super Pillar with thermoelectric separation concepts, to bypass dielectric and conduct heat directly through copper pillar to copper plate at the bottom. In this design, heat can be quickly take-away from components and dissipated through copper plate at the bottom.

get more info

get more info