Main Menu

E-mail:sales@scmcpcb.com

Website :www.scmcpcb.com

Skype:sc.mcpcb

No minimum order quantity

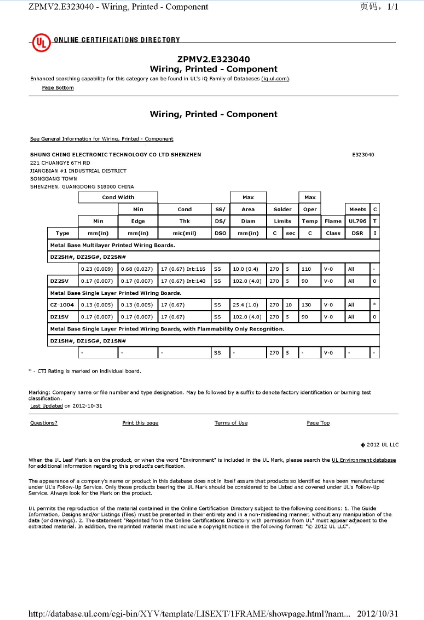

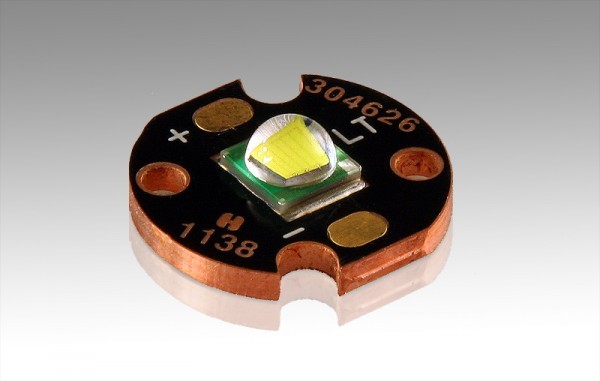

We have UL certification ,ISO14001:2004 and TS16949 certification. Shung Ching Electronic has been producing Aluminum Printed Circuit Boards (also called Metal base PCBs) for over a decade. Although originally envisioned for use in the power-supply industry these substrates are now most widely used in High Brightness LED products. There are many names for these products; Aluminum clad, aluminum base, Metal clad(MCPCB),Insulated Metal Substrate(IMS or IMPCB), Thermally conductive PCBs, etc… but they all mean the same thing. A thin layer of thermally conductive but electrically insulating dielectric is laminated between a metal base and a copper foil. The copper foil is etched into the desired circuit pattern and the metal base draws heat away from this circuit through the thin dielectric.

As Metal Core PCB means the base material for PCB is metal,not normal FR4/CEM1/3, etc, and currently

the most commonmetal

used are Aluminum, Copper alloy. Aluminum has good heat transfer and dissipation ability, but yet relatively cheaper.

On the other hand, copper has even better performance but relatively more expensive.

Therefore, majority of MCPCB are made of aluminum.

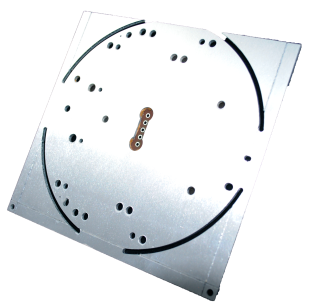

MCPCBs are used instead of traditional FR4 or CEM3 PCBs because of the ability to efficiently dissipate

heat away from the components. This is achieved by using a Thermally Conductive Dielectric Layer.

The main difference between a FR4 board and MCPCB is the thermally conductive dielectric material in the MCPCB.

This acts as a thermal bridge between the IC components and metal backing plate.

Heat is conducted from the package through the metal core to an additional heat sink.

On the FR4 board theheat remains stagnant if not transferred by a topical heat sink.

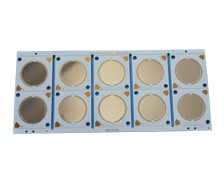

Advantage of MCPCB

1.High Heat dissipation

Some LEDs dissipate between 2W and 5W of heat and failures occur when the heat from a LED is not properly removed; a LED’s light output is reduced as well as degradation when the heat remains stagnant in the LED package. The purpose of a MCPCB is to efficiently remove the heat from all topical IC’s (not just LEDs). The aluminum base and thermally conductive dielectric layer act as bridges between the IC’s and heat sink. One single heat sink is mounted directly to the aluminum base eliminating the need for multiple heat sinks on top of the surface mounted components.

2. High Thermal Conductivity

Thermal expansion and contraction is the common nature of the substance, different CTE is different in thermal expansion. As its own characteristics, aluminum and copper have unique advance than normal FR4, thermal conductivity can be 0.8~3.0 W/c.K.

3. Dimensional Stability

It is clear that the size of the metal-based printed circuit board stabler than FR-4 , CEM-1,

CEM-2 and CEM-3. The size change of 2.5 ~ 3.0% when Aluminum PCB and aluminum sandwich panels was heated from 30 ℃ to 140 ~ 150 ℃.